What is the solution?

Using low-impact methods to raise naturally-fed dairy cows in mountain pastures and produce Macagn cheese.

This solution improves our resource security in the food category.

How does it #MoveTheDate?

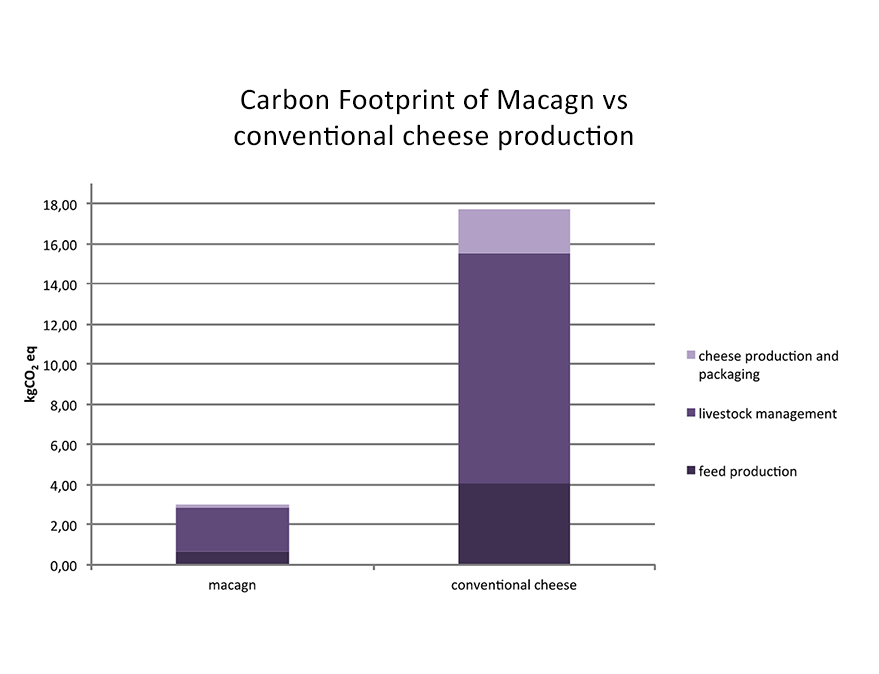

The Carbon Footprint of a wheel of Macagn cheese (between 1.7 and 2.3 kilos in weight and between 18 and 25 centimeters in diameter) is 83% lower than that of other conventional cheeses. Its production emissions are fully offset by the carbon uptake of the producing farm’s ecosystems.

How is it scalable?

Conventional cheese production operations far outnumber small-scale farms such as those which produce Macagn, leaving much room for the adoption of such operations. However, those farms’ lower biogenic emissions are dependent on a lower yield compared to conventional farm management.

What is the solution?

Using low-impact methods to raise naturally-fed dairy cows in mountain pastures and produce Macagn cheese.

This solution improves our resource security in the food category.

How does it #MoveTheDate?

The Carbon Footprint of a wheel of Macagn cheese (between 1.7 and 2.3 kilos in weight and between 18 and 25 centimeters in diameter) is 83% lower than that of other conventional cheeses. Its production emissions are fully offset by the carbon uptake of the producing farm’s ecosystems.

How is it scalable?

Conventional cheese production operations far outnumber small-scale farms such as those which produce Macagn, leaving much room for the adoption of such operations. However, those farms’ lower biogenic emissions are dependent on a lower yield compared to conventional farm management.

Macagn takes its name from one of Monte Rosa’s foothills in Italy, though it is made in the Cervo, Sessera and Sesia valleys. A typical mountain cheese, it is made from full-fat, raw cow’s milk. Its most significant feature is that the cheese is made immediately after each milking, a method probably developed to take advantage of the fresh milk’s natural heat in mountain dairies where it would be difficult to keep it warm. Since the milk is processed immediately after milking, the finished cheese has scents of grass and wildflowers.

Macagn takes its name from one of Monte Rosa’s foothills in Italy, though it is made in the Cervo, Sessera and Sesia valleys. A typical mountain cheese, it is made from full-fat, raw cow’s milk. Its most significant feature is that the cheese is made immediately after each milking, a method probably developed to take advantage of the fresh milk’s natural heat in mountain dairies where it would be difficult to keep it warm. Since the milk is processed immediately after milking, the finished cheese has scents of grass and wildflowers.

The Slow Food Presidium safeguards traditional Macagn and gives proper recognition to the cheesemakers who continue to produce it despite the difficult conditions in mountain dairies. The production protocol specifies that the milk is processed after each milking. The cows, hardy breeds suited to mountain pastures, must be fed a natural diet.

Starting in 2013, Italy-based INDACO2 began its collaboration with the Slow Food Presidium project to assess the environmental impact of the Presidum’s products. Livio Garbaccio, based in Varallo (Piedmont, Italy), is one of the Presidium cheese producers. He manages 25 cows on his family-run farm, for an annual output of 3.780 wheels. His farm employs low-impact techniques, including milking by hand, primarily feeding his herd with fresh mountain grass and hay, creating bedding from leaves instead of straw, using stream water in the cheesemaking process, and producing electricity with renewable sources.

INDACO2 determined that the total Carbon Footprint of a 2 kg wheel of Macagn is equivalent to the emissions generated in a car trip of over 8km and that the carbon Footprint of a wheel of Macagn is approximately 83% lower than that of conventional cheese. Moreover, the emissions generated by this specific farm are fully offset by the carbon uptake of the farm’s plant ecosystems (woodland, meadows, and arable land).

More details about the assessment are available in the Analysis of the Life Cycle and Carbon Footprint of Slow Food Presidium Products report.

More details about the assessment are available in the Analysis of the Life Cycle and Carbon Footprint of Slow Food Presidium Products report.

*The responsibility for correctness of data used to calculate this result lies with INDACO2. Only the carbon Footprint component of the Ecological Footprint was considered in this calculation. Results may differ if recalculated with data for all Footprint components. The feasibility of substituting all global consumption of this product with the alternative product outlined on this page was not investigated as part of this study; additional research is needed to fully understand the extent to which each alternative product can be replicated and scaled up.

Funded by the European Union. Views and opinions expressed are, however, those of the author(s) only and do not necessarily reflect those of the European Union or CINEA. Neither the European Union nor CINEA can be held responsible for them.

There’s no benefit in waiting!

Acting now puts you at a strategic advantage in a world increasingly defined by ecological overshoot. Countless solutions exist that #MoveTheDate. They’re creative, economically viable, and ready to deploy at scale. With them, we can make ourselves more resilient and #MoveTheDate of Earth Overshoot Day. If we move the date 6 days each year, humanity can be out of overshoot before 2050.